96% Faster Schedule Creation with AI Powered BIM Automation

An advanced monitoring solution built to reduce stillborn rates,

protect sow health, and maximize farm productivity.

Client Overview:

A leading MEP consultancy was working on a multi tower commercial development

multiple levels, thousands of pipe routes, and dozens of linked Revit files across

disciplines. The design team had completed coordinated plumbing layouts, but

construction scheduling and fabrication planning were stuck

Their challenge wasn t the design.

It was data extraction.

Every fabrication cycle required:

- Identifying all pipes and fittings from merged Revit models

- Reconciling inconsistent naming conventions

- Mapping materials and sizes

- Manually creating category-based schedules

- Formatting Excel sheets for contractors

A process meant to support construction had become its biggest blocker.

The Challenge:

When the project reached the construction planning phase, the team had to merge plumbing models from two different levels—each built by separate consultants using different family standards.

The result?

And even then, inconsistencies slipped through.

The team needed a way to extract clean, organized, fabrication-ready data—accurately and at scale.

1. 40,000+ elements spread across misaligned models

Manually filtering pipes and fittings became nearly impossible.

2. Inconsistent material & size parameters

What should have been “CPVC32 mm existed under four different naming conventions.

3. Inconsistent fitting types

Reducers, elbows, tees, and

transitions had mismatched

categories, causing schedule

errors.

4. Heavy manual formatting for Excel output

Fabrication teams needed category-sorted, code-driven output—but Revit exports were messy and unusable.

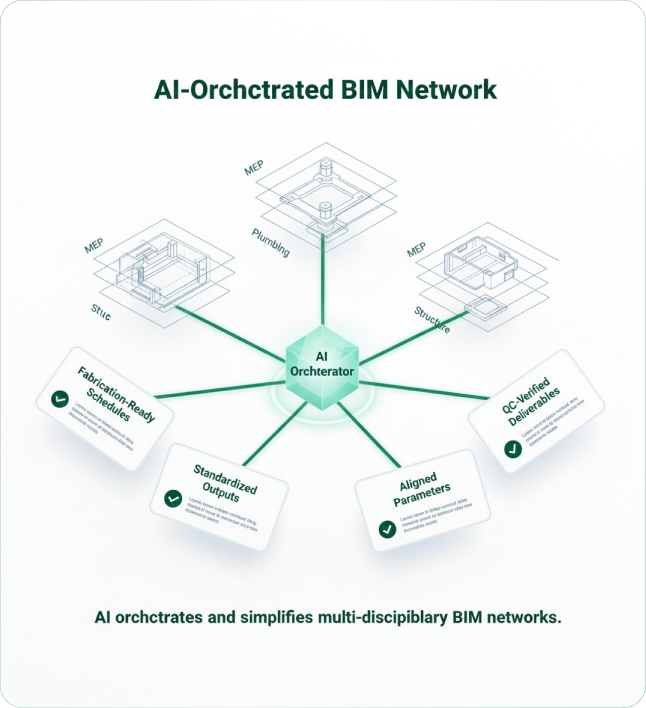

The Solution: Deploying Our AI-Driven Schedule Builder

We introduced the client to our AI-powered Schedule Builder, part of our larger BIM Engineering Automation Platform.

Within minutes, the system began solving problems that previously required entire working days.

1. Smart Category Extraction

It scanned all plumbing systems across the merged models and auto-identified:

It scanned all plumbing systems across the merged models and auto-identified:

- Pipes

- Fittings

- Reducers

- Elbows

- Tees

- Connectors

- Transitions

- No manual filtering, no guesswork.

2. Auto-Mapping Materials & Sizes

The AI normalized naming conventions and standardized every material and diameter value—ensuring a single source of truth.

3. Auto Code Generation for Fabrication

Every component received a unique code, instantly aligning with the contractor s internal fabrication system.

4. Automated View Creation & Filtering

The tool generated system-wise and size-wise filters so teams could QA data easily.

5. Excel Export With Zero Manual Clean

Clean, sorted, fabrication-ready Excel files were produced-with all formatting applied automatically.

The Impact: From 2 Days → 30 Minutes

With the Schedule Builder, the team achieved measurable, transformative results

40,000+ pipe & fitting elements extracted and organized automatically

A task previously managed by two engineers over two days.

Fabrication ready schedules generated in under 30 minutes

Reduction in turnaround time: 96%

Zero formatting errors

Clean Excel outputs required no additional rework.

Complete category, size, and material alignment across both models

Eliminated all conflicts caused by inconsistent parameters.

Standardized data for future project phases

The output became a reusable template for further levels and towers.

Client Outcome:

Scheduling Is No Longer a Bottleneck

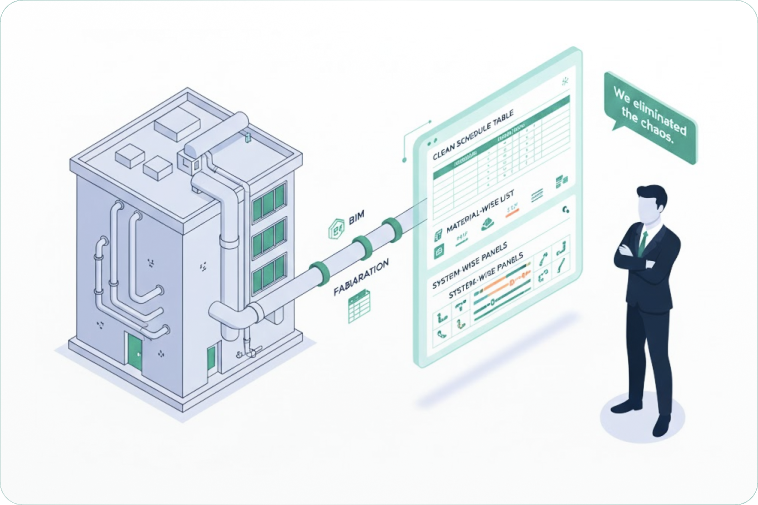

Once implemented, the BIM Manager noted:

“We didn t just save time-we eliminated the chaos.

For the first time, our schedules matched exactly what

the fabrication team needed.”

The platform is now deployed across multiple ongoing

projects, dramatically accelerating planning cycles and

improving coordination quality.

Why this case matters

Scheduling Is No Longer a Bottleneck

This project demonstrates a larger industry shift.

Complex, multi-disciplinary BIM models are becoming the norm.

Manual scheduling workflows are not.

The AI-driven Schedule Builder represents the next evolution in MEP engineering:

- Automating repetitive tasks

- Standardizing outputs

- Eliminating error-prone manual steps

- Speeding up project delivery

- Creating high-trust data pipelines for fabrication teams

For organizations managing large BIM workloads, this tool isn’t just helpful—

it’s essential for staying competitive.